British Nuclear Fuels – Sellafield

A major challenge for the global nuclear industry is to process and safely store legacy, current and future nuclear waste. That include packaged waste of different nature, some of which aligned for long-term geological disposal.

One of the most complex challenges for the industry is to characterise the contents of these shielded waste containers. Containing cemented or vitrified waste, these highly engineered packages have been designed to prevent the radiation stored within from escaping out into the environment, which therefore makes the use of conventional imaging techniques difficult, if not impossible.

With those constraints, improving waste classification, reduce storage costs or mitigate the risks associated with containment breaches, which would mandate a large-scale decontamination and repackaging programme at significant expense, is a tall order.

A new in situ characterisation method is here needed for a better evaluation of the contents of radioactive waste containers Ideally, the implementation of high precision imaging will allow for the optimisation of post-dismantling radioactive waste management and a marked reduction on associated disposal costs.

Use Case – NNL Cemented Product Imaging

NNL Central Laboratory, Sellafield site, Seascale, UK

- ILW drums designed for long-term storage, containing cladding material stripped from uranium fuel rods encapsulated within concrete grout.

- An unknown proportion of this inventory may contain fuel fragments. The natural expansion of these decaying uranium fragments over time may threaten the containment of this waste form.

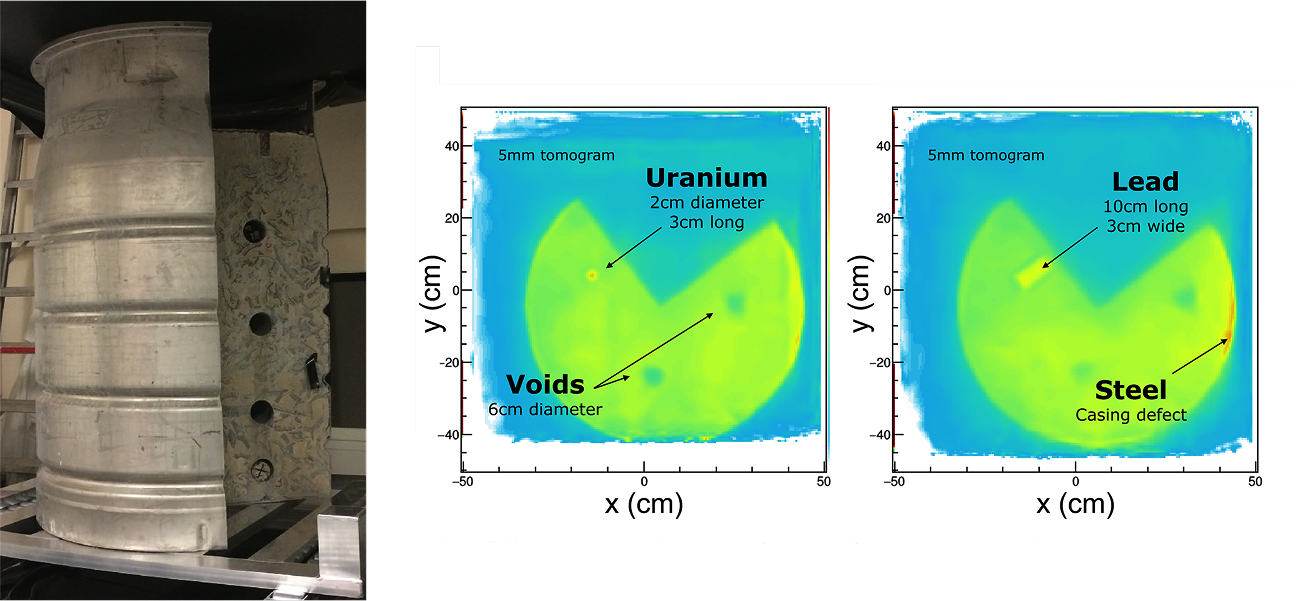

- Passive inspection of 500-litre stainless steel ILW mock-up drum with 4 horizontal cores (2 extra vertical cores are not pictured).

- Density variations are observed within the concrete and magnesium oxide matrix, highlighting the size and localisation of fragments.

-

University of Glasgow and UKNNL pushed the boundaries of what we thought was possible when we first funded their pioneering R&D [in 2009].

They never overpromised, but greatly overachieved. They’re a team that can be trusted. We’re so excited and proud to see muography making a strong, positive impact within the nuclear industry today.

Hats off to Lynkeos for that!

Mark Downson (Business & Technology Manager ) / John Jowsey (Senior Technology Manager - retired)Sellafield Ltd -

Sellafield’s collaborative relationship with Lynkeos, through UKNNL, has helped us solve a complex engineering challenge, of monitoring the evolution of legacy waste in interim storage without breaching containment by using muography.

Lynkeos has a history of delivering expertise and bespoke alterations to the technology to enable deployment in demanding environments, whilst maintaining the values that Sellafield wish to see in everyone that works with us to fulfil our purpose.

Alex Allen (Technical Manager, CM&I Lead, SL Retrievals Technical)Sellafield Ltd -

UKNNL’s Central Laboratory at Sellafield is home to a world-first deployment of a CE-Certified muography system – the Lynkeos Muon Imaging System – on a nuclear licensed site.

Our close working relationship with Lynkeos over the years helped to turn this from concept into reality. The strength of our collaboration for over a decade has been recognised by our joint award of the Powerful Partnership Award at the Scottish Knowledge Exchange Awards 2023.

A key factor in our joint success has been our continued professional engagement. This has enabled UKNNL and Lynkeos to develop cutting-edge innovative technology that meets the needs of our customers and makes a real difference in nuclear.

Craig Shearer (Radiochemistry Capability Leader – Fuels, Reactors & Recycling)United Kingdom National Nuclear Laboratory (UKNNL) -

UKNNL has worked closely with Lynkeos for several years to support the commissioning of a muon scanning system in our Central Laboratory at Sellafield.

The introduction of muon scanning technology has proven to be an excellent example of technology crossover into the nuclear industry, improving safety when testing waste materials. Scanning using muons can avoid unnecessary intrusive sampling, which minimises radioactive dose uptake and spread of contamination from the waste product.

The system at Central Laboratory has scanned radioactive waste blocks from thermal treatment operations and therefore reached Technology Readiness Level (TRL) 7 in our facility. It’s great to have Lynkeos as a partner in this groundbreaking work.

Sean Clarke (Head of Capability, Waste Management and Decommissioning)United Kingdom National Nuclear Laboratory (UKNNL)